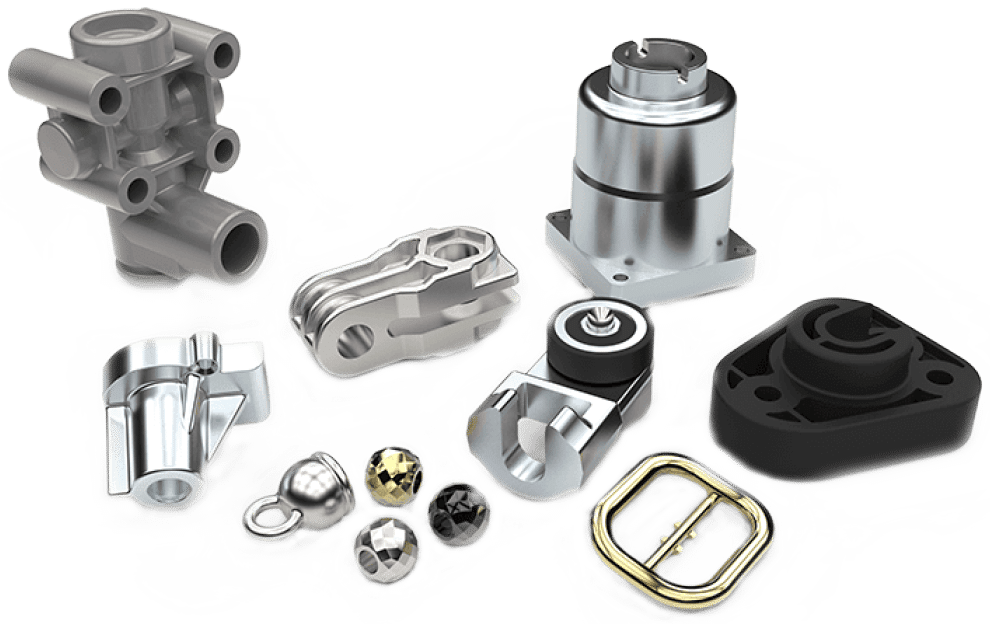

The company has a Zamak Injection section with Hot Chamber Pressure Injection machines, with a range of possibilities of up to 900 grams of capacity. All these machines are automatic and they also have peripheral equipment to handle the tasks of separating and recovering the casting, all in a continuous manner and as and when the parts are being injected.

All the manufactured parts which do not require a special polishing treatment are treated in our mass-polishing section. We have a traditional polishing by vibration system which gives our parts a surface finish that is perfect for a subsequent galvanic treatment.

We have the great advantage that we manufacture our own Zamak injection moulds, which results in a correct control of the process. Likewise, our customers leave the maintenance of these moulds in our hands, which guarantees them a controlled quality of the piece at all times.