Fabricación de moldes

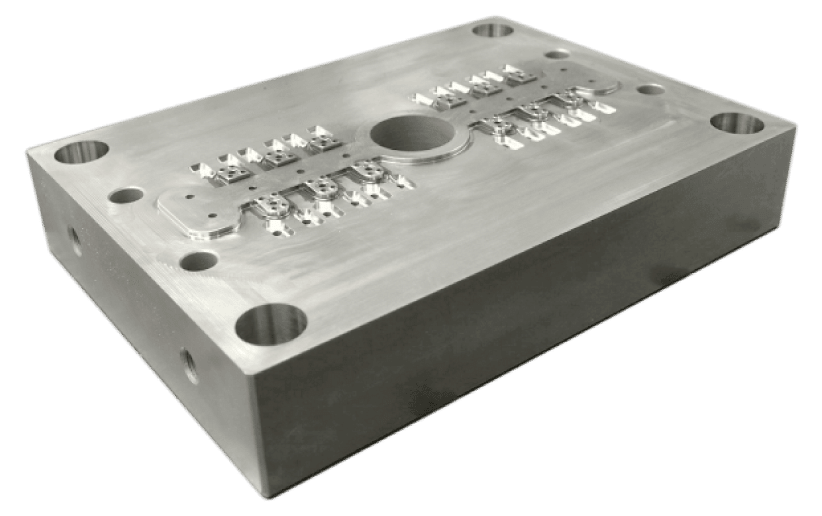

Como un perfecto engranaje. La fabricación de piezas para maquinaria requiere de una sincronización perfecta entre todos los elementos que forman parte de una cadena de trabajo. Una de las principales apuestas que han convertido a Joviar en uno de los referentes de su sector es la fabricación de moldes de alta precisión. Disponemos de un taller completamente robotizado donde se confeccionan las herramientas que tu industria o empresa necesita.

Amplios y dotados centros de alta velocidad que trabajan directamente sobre el metal, sea aluminio, acero o zamak de cualquier tipo de dureza. Lo que nos permite obtener un resultado profesional que

responde a las exigencias de cualquier cliente. La fabricación de moldes no es algo nuevo. Con las máquinas más robustas y fiables del mercado, de última tecnología y equipadas de periféricos de última generación, Joviar automatiza el proceso de inyección de metal fundido para la fabricación de moldes.

Los mejores materiales

Una vez diseñado en nuestra empresa el molde de la pieza a fabricar, se analizan las necesidades del mismo y en base al resultado, se seleccionan entre nuestros proveedores los materiales de la mejor

calidad que se necesitarán. Gracias a la simulación en el llenado se consigue una mejora ostensible en la calidad de los moldes y en la estabilidad dimensional de las piezas. La especialidad de Joviar es la confección de moldes de inyección de piezas de zamak y aluminio, de gran exigencia técnica y complejidad.

La mecanización del trabajo

Para ello resulta necesario conocer y entender la mecánica y complejidad de las máquinas industriales que confeccionan los moldes, su mantenimiento y los problemas del proceso productivo. Joviar aplica toda su experiencia y tecnología de simulación de llenado para la fabricación de piezas que logran reducir los ciclos y mejorar la calidad de los moldes. La mecanización del trabajo comporta una serie de ventajas que permite el ahorro de tiempo y dinero. El uso de herramientas y componentes controlados por un ordenador permite llevar a cabo múltiples operaciones en una pieza con una mínima intervención humana.

Reducción de los costes de producción

Se reducen los costes de producción al invertir menos horas de trabajo. Pero no por ello se descuida la precisión en el modelado; todo lo contrario. La eficacia es una de las características de la

mecanización en la fabricación de moldes que realizamos en Joviar. La finalidad de todo proceso de mecanización es la productividad. Ya sea de frenado, taladrado, ranurado u otros procesos de corte de metal, la realización de las órdenes recibidas mecánicamente permiten llevar a cabo múltiples operaciones sobre una pieza, utilizando para ellos herramientas rotativas de múltiples filos de corte. Son más precisas, seguras, dejan menos residuos y se disminuye el número de errores.

Tanto o más importancia que la eficacia tiene el detalle en el resultado final. Las máquinas de electroerosión de penetración permiten a Joviar trabajar minuciosamente el detalle. Una empresa que controla en todo momento el proceso de centrado y la precisión en el modelado de la pieza o molde.