Zamak Injection

The manufacture of technical parts in ZAMAK

Our main activity is the manufacture of technical parts in Zamak. We have been providing our customers with products of the highest quality since 1956. At Creaciones Joviar we specialise in Hot Chamber Zamak Injection Pressure machines. Over the course of more than 60 years of experience, we have expanded our manufacturing possibilities and today we have at our disposal a battery of 9 machines, from 5 to 125 Tons, which means we can manufacture parts weighing up to 900 grams.

We are experts in:

Zamak Injection

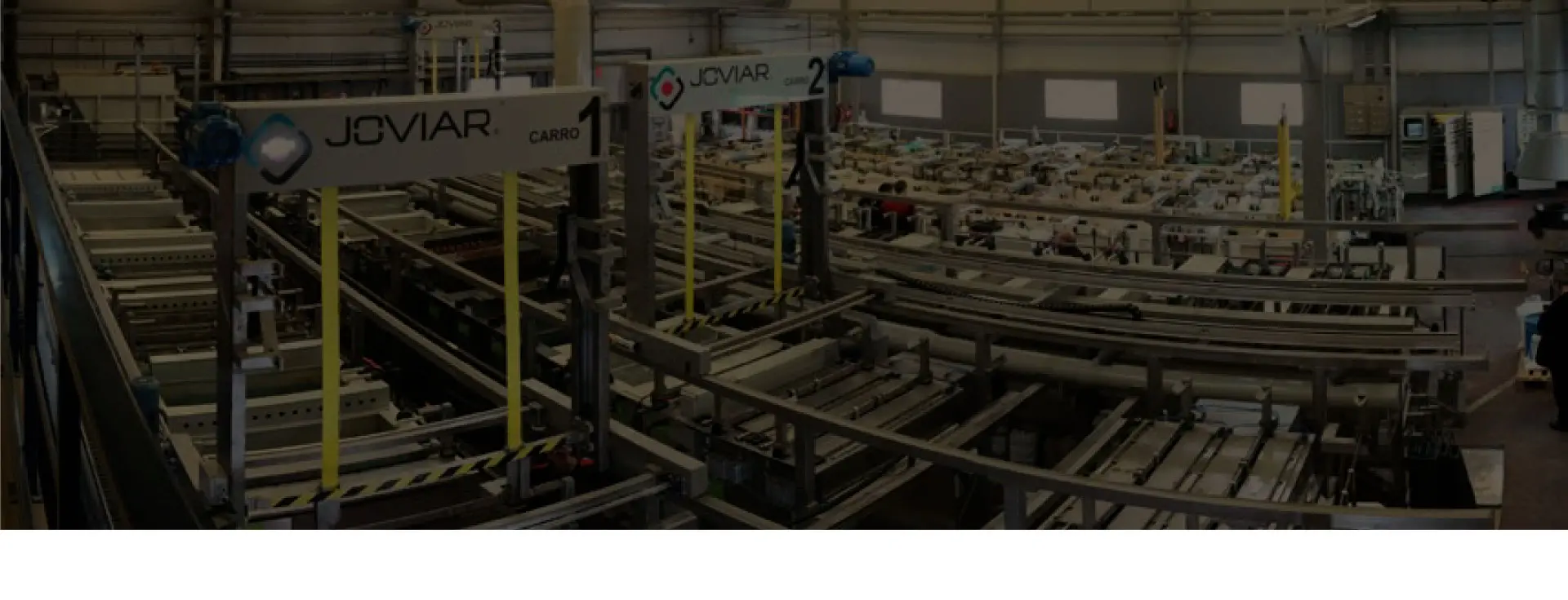

The company has a Zamak Injection section equipped with Hot Chamber Pressure Injection machines, with a range of possibilities of up to 900 grams of capacity. All these machines are automatic and they also have peripheral equipment to handle the tasks of separating and recovering the casting, all in a continuous manner and as and when the parts are being injected.

Zamak Injection

The company has a Zamak Injection section equipped with Hot Chamber Pressure Injection machines, with a range of possibilities of up to 900 grams of capacity. All these machines are automatic and they also have peripheral equipment to handle the tasks of separating and recovering the casting, all in a continuous manner and as and when the parts are being injected.

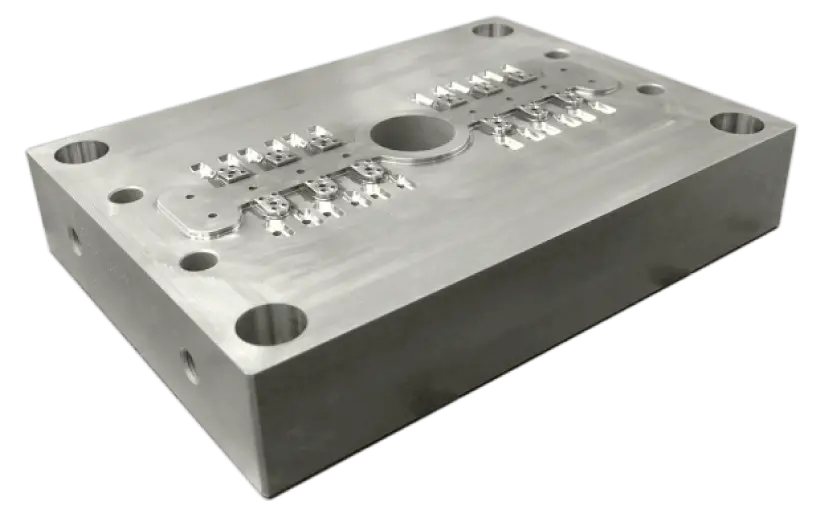

The Manufacture of Moulds

We have a complete workshop dedicated to the manufacture of moulds, fully robotized and equipped with the latest advances in measurement control and part positioning. Among our machines we have two high speed Machining Centres which allow us to work directly on high hardness steels with the resulting reliability insofar as the finishing of the moulds is concerned.

The Manufacture of Moulds

We have a complete workshop dedicated to the manufacture of moulds, fully robotized and equipped with the latest advances in measurement control and part positioning. Among our machines we have two high speed Machining Centres which allow us to work directly on high hardness steels with the resulting reliability insofar as the finishing of the moulds is concerned.

Electrolytic Finishes

Within our company we have an extensive section dedicated to the treatment of surfaces, consisting of a Galvanic Plant with more than 70 stations with which we offer a range of over 25 different surface finishes. We have also enhanced our electrolytic finishing section with a new Galvanic Plant with Frames, which with its more than 74 stations offers a range of high quality finishes (Nickel, Chromium, Gold) both in gloss and satin.

Electrolytic Finishes

Within our company we have an extensive section dedicated to the treatment of surfaces, consisting of a Galvanic Plant with more than 70 stations with which we offer a range of over 25 different surface finishes. We have also enhanced our electrolytic finishing section with a new Galvanic Plant with Frames, which with its more than 74 stations offers a range of high quality finishes (Nickel, Chromium, Gold) both in gloss and satin.

Oriented towards excellence and improvement

The company’s management believes that it is crucial to follow a Quality Control system that gains the trust of all its customers. Everyone at the company, both the management and the entire workforce, are quite determined that this should be so, and we are all completely committed to obtaining quality products which meet all our customers’ expectations.

Faced with the challenge of the ever-growing competition in this field, CREACIONES JOVIAR operates a Quality Management System based on the UNE EN ISO 9001 standard, with the intention of guaranteeing the satisfaction of its customers and achieving continuous improvement within the organization, based on process optimisation.

We are associated with

The company CREACIONES JOVIAR S.L. has been the beneficiary of a grant of €61,091.42 corresponding to the project called: Circular Economy through industrial symbiosis of strategic sectors of the Valencian Community within the Consolidation of the business value chain line within the framework of aid from the Valencian Agency of the innovation”

The company CREACIONES JOVIAR S.L. has carried out the “Implementation of a sinking EDM machine” which has been financed by the Ministry of Sustainable Economy, Productive Sectors, Commerce and Labor included within the aid program to improve the competitiveness and sustainability of industrial SMEs in the sectors of the Community Valenciana of footwear, ceramics, metal-mechanics, textiles, toys, marble-natural stone and aggregates, wood – furniture and lighting, chemicals, automotive, plastic, containers and packaging, paper and graphic arts, waste recovery and the emerging sectors of biotechnology, audiovisual production and video game production, within the fourth phase of implementation of the Strategic Plan for the Valencian industry. The project has been supported with a grant of €50,155.00 with the aim of improving the supply and quality of the products offered by the company.